3D design example: Difference between revisions

Brian Wilson (talk | contribs) mNo edit summary |

Brian Wilson (talk | contribs) mNo edit summary |

||

| Line 1: | Line 1: | ||

I have done perhaps 2 dozen designs now, bicycle parts, car parts, furniture parts. | |||

Lots of fun. This is the first time I have documented anything. [[User:Brian Wilson|Brian Wilson]] ([[User talk:Brian Wilson|talk]]) 07:51, 13 January 2014 (PST) | |||

== The problem == | == The problem == | ||

Revision as of 15:51, 13 January 2014

I have done perhaps 2 dozen designs now, bicycle parts, car parts, furniture parts. Lots of fun. This is the first time I have documented anything. Brian Wilson (talk) 07:51, 13 January 2014 (PST)

The problem

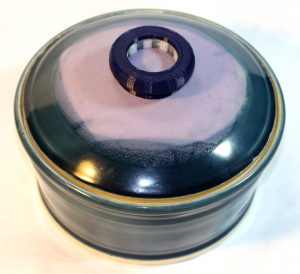

We got a bowl from a rejects pile from a neighbor who does porcelain ceramics. We're guessing it was a reject because the handle on the lid is too small for human fingers.

So this is the story of using a $2000 Makerbot Replicator 2 to fix a $5 bowl. :-) Great way to learn, in this case, it's the second project I've done with nylon, and the first in which I combine two materials, PLA and nylon.

Here is the bowl.

The lid is askew a bit because the lid from solution #1 is hiding underneath.

The tools

- CAD software: OpenSCAD

- Printer: Makerbot Replicator 2

- Filament: Dark blue PLA, white nylon

I use this Starrett 799 caliper on every project. It is my favorite instrument.

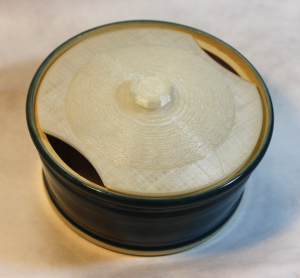

Solution #1, a new lid

Here is the bowl and a lid I printed for it shortly after I got the printer. It is one of my first designs.

Problem #1: The printer is not big enough so I had to make "vents" on each side.

Problem #2: When used in a microwave. steam from heated food is absorbed into the PLA, so it warps.

This PLA is not food grade so I did not really want it in contact with food anyway.

Solution #2

This is the idea we came up with yesterday. Make a knob that attaches to the existing handle but is easy to grip. It's outside the bowl, so no problems with food contact and no contact with steam so (hopefully) no warping.

Design issues

So far nearly everything I print requires several iterations. This one was no exception.

Design #1 - One piece, all PLA

This one has fingers that are supposed to grip the knob. They are too brittle, so when I tried to snap the knob onto the lid, they snapped off.

PLA is brittle but has a nice hard smooth surface.

On the other hand nylon is soft and flexible. I just got some nylon filament (Taulman 618). This inspired me to try making a two piece part. Nylon fingers to grip the handle on the lid, and a PLA knob to hold the fingers in place.

Design #2 - PLA + Nylon

Code for this handle is here: OpenSCAD for bowl handle

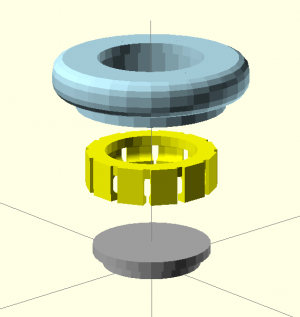

Normally when working on a design, I first create a reasonably accurate model of the existing thing, in this example, the handle on the lid. This allows me to visually check fit as I design the actual part(s) that will be printed.

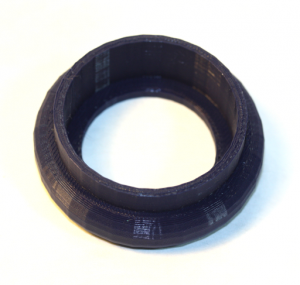

PLA handle - This will be the outer part that gives your fingers a place to grip. A tube pushes down over the nylon insert, locking the soft hooks on the insert into place.

I put a hole in the middle mostly to reduce the amount of plastic required. It also reveals how the parts work once it is assembled.

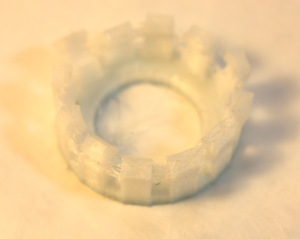

Nylon insert

To understand why the insert in design #2 fails, you have to think about how 3D printing works. Software converts your 3D model into layers. A thin bead of plastic is squirted out an extruder (just like a glue gun) to form each layer.

This means when I tried to push sideways on the fingers, they just parted on the join between the horizontal layers. Snapped right off! Some of them broke at the base and some broke at the thin spot.

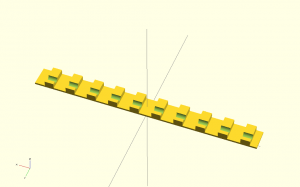

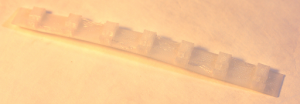

Design #3 - PLA + Nylon strip

To get around the shear problem, I printed a flat nylon strip. Then I wrap it around the lid handle, and push the PLA knob down over it.

This works because when building up the flat strip, the successive layers are run at angles, the first layer is at 45 degrees and the next is at -45, so the resultant strip is very flexible and can be bent into a tube.

It works!

Careful measurements and a good design are not enough, to make a functional part, you have to understand how the printer and the materials work together.